What is a Durometer? Its Types, Parts And Definition

We will explain that what is a durometer and what is it for? with its types and parts to better learn about durometer. Lets Read Physics..

What is a durometer?

The durometer, as its name indicates, is a measuring instrument dedicated to testing and measuring the hardness of different types of materials. They are capable of measuring materials such as metals, plastics, rubbers, elastomers, among others.

Hardness is the property of materials that is defined as: resistance to permanent penetration under some static or dynamic load that a material has.

How does it work?

The operation is based on exerting a load on the surface of the material to be measured through a penetrating element.

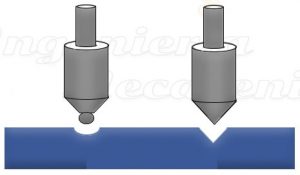

Once the object to be measured has been selected, a type of hardness penetrator must be chosen (there are two types. A spherical steel ball and a conical one for harder objects). The durometer exerts a force on the surface which will leave a mark, once the load ceases, the depth is measured. To know the hardness of the material.

Parts of a durometer

Since there are different types of durometers, their composition can vary but we can always find some main parts.

- Body: It is responsible for generating the load that is exerted on the material. All loads have to be standardized.

- Penetrating or indentering element: This is in charge of leaving the mark on the material.

- Indicator: As its name says, it is responsible for indicating the hardness obtained during the measurement process. This indicator also shows us information about what type of indenter to use.

Types of Durometers

Types of Durometers

We can find different levels of hardness and that is why for each of these there is a different durometer.

Shore Durometer

Its name is due to the fact that the scale of this instrument was defined by Albert Shore, once the mark is left on the material. the depth is transmitted to a spring in a dial gauge, which gives us a certain hardness value.

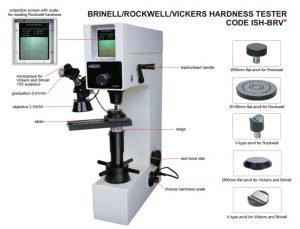

Rockwell Durometer

This type is capable of measuring any metal or alloy. both hard and soft. Its method of operation is to initially exert a small load, which increases the accuracy of the measurement, and subsequently exert a greater load.

Brinell Durometer

This instrument is used with a hard spherical indenter and the load is constant, the diameter of the fingerprint is measured with a microscope and converted to a specific HB number using a formula.

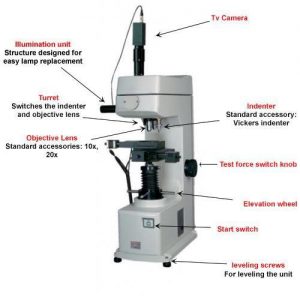

Vickers Durometer

The main principle is to observe the resistance of the material to deformation. This durometer is considered microhardness. The resulting fingerprint is measured with a built-in microscope and transformed to HV or DPH hardness using a formula.

These durometers incorporate an image analyzer through a computer which analyzes the location of the fingerprint, makes the operations of the hardness values and graphs the information obtained.

Knoop Durometer

This durometer is similar to the Vickers, the only difference is that a much smaller sample is needed in the material to be able to measure the hardness.

Leeb Durometer

This instrument leaves a smaller footprint than all the others since its operation is characterized by reading the energy loss in a defined impact after hitting the sample. This means that this device generates an initial impact and when hitting the material, impact energy is lost and this loss is measured to later convert it to hardness.